Lesson 2: Creating the Phytosanitary Certificate Using the Certification Process

Topic 3: Step 3: Verify the Shipment Meets the Entry Requirements

In this topic, you will learn about the third step in the phytosanitary certification process: verifying that the shipment meets entry requirements.

Objective:

- Participants will recognize that this step involves investigation of both paperwork and the physical commodity itself.

Now that Exportland has gathered the berry import requirements for Importland, the certifying official must verify that the importing country’s entry requirements are met by the shipment to be exported as outlined in the export application. This is done through inspection of supporting documentation from the first two steps we’ve completed, and physically inspecting the commodity itself.

Inspection of Supporting Documentation

Section 3.1 of ISPM 7 states:

“Except for the issuance of phytosanitary certificates, non-governmental personnel may be accredited by the NPPO to carry out specified certification functions. To be accredited, such personnel should be qualified and skilled and responsible to the NPPO. To ensure independence in their exercise of official functions, they should be subject to restrictions equivalent to those for government officials and have no financial interest in the outcome.”

ISPM 7

The certifying official will often need to review supporting documentation that accompanied the application for certification. During the review, he or she will need to ask the following questions:

- Does the supporting documentation come from acceptable (accredited or official) sources?

- Is the documentation sufficient to meet the entry requirements?

Here are a few examples of supporting documents that a certifying official may review.

- Phytosanitary certificates issued by another country (for re-exports)

- Treatment certificates

- Laboratory certificates or results

- Inspection certificates from government or accredited sources

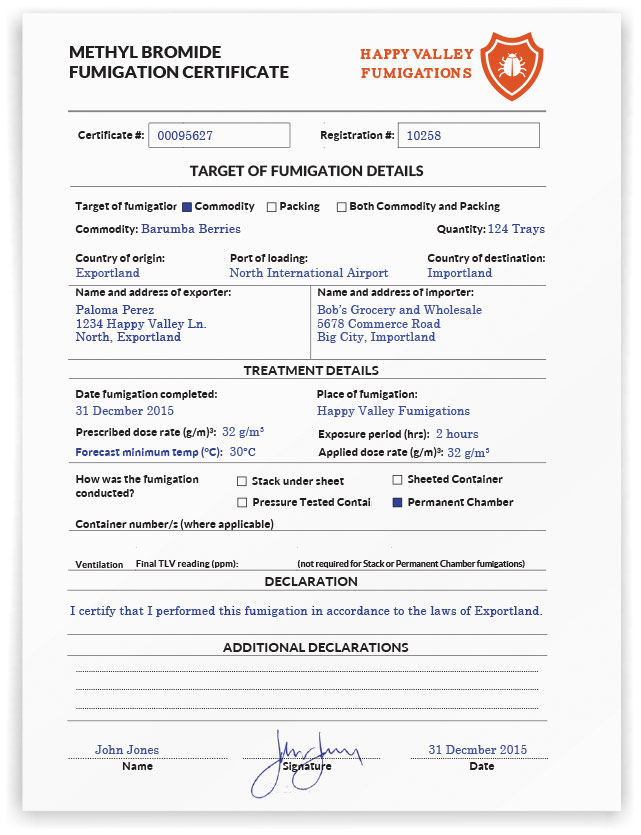

For our example, Paloma Perez has provided a fumigation treatment certificate with her export application, as seen below. Please be aware that methyl bromide is damaging to the environment, and thus, it is being phased out as a fumigation chemical in many countries. However, it is still used often enough that you may still see it in practice for a few more years; therefore, we have used it just for illustration in this example.

It is the certifying official’s responsibility to evaluate whether or not the phytosanitary measures recorded provide sufficient evidence to support the declaration that the shipment meets the importing country’s requirements. The certifying official must have the authority, and be willing, to forgo certification if the necessary phytosanitary measures were not performed or if there is any doubt about the validity of the accompanying documentation.

Physical Inspection of the Commodity

Often a physical, visual, inspection of the commodity is required, in addition to supporting documentation to assure both that the shipment is free of pests (i.e. weed seeds, insects, disease signs/symptoms, and soil) and to comply with the certification statement. Paperwork is a good indicator of compliance, but it does not replace physical inspection in most cases. We will consider the certifying statement more fully later in this module.

Very little guidance for conducting an export inspection is given in ISPM 7 and ISPM 12. ISPM 23 goes a little further and states:

“As inspection of entire consignments is often not feasible, phytosanitary inspection is consequently often based on sampling… The size of a sample for inspection purposes is normally determined on the basis of a specified regulated pest associated with a specific commodity. It may be more difficult to determine the sample size in cases where inspection of consignments is targeted at several or all regulated pests.”

ISPM 23

This means that higher pest risk commodities should be inspected at a higher rate (larger sampling size) than lower pest risk commodities. For example, nursery stock is considered extremely high risk and should be inspected at 100% of the consignment or as close to 100% as feasible. Generally, low risk commodities are inspected at 2% of the shipment’s inspectional unit (i.e., boxes, units, bags, tray packs, etc.). Low risk commodities in extremely large consignments can be inspected using a hypergeometric table derived from ISPM 31. This is what the table looks like.

Hypergeometric Table for Random Sampling

| Total number of inspectional units: | Randomly select this number of units to inspect: |

|---|---|

| 1 – 13 | Inspect all units |

| 14 – 15 | 13 |

| 16 – 17 | 14 |

| 18 – 19 | 15 |

| 20 – 22 | 16 |

| 23 – 25 | 17 |

| 26 – 28 | 18 |

| 29 – 32 | 19 |

| 33 – 38 | 20 |

| 39 – 44 | 21 |

| 45 – 53 | 22 |

| 54 – 65 | 23 |

| 66 – 82 | 24 |

| 83 – 108 | 25 |

| 109 – 157 | 26 |

| 158 – 271 | 27 |

| 272 – 885 | 28 |

| 886 – 200,000 | 29 |

Even though the sampling for these large consignments is random, using the table provides some consistency for your search and inspection methods.

After determining the phytosanitary requirements of the importing country, the certifying official must verify that the goods to be exported meet all of those requirements. Any paperwork that the exporter may have included about phytosanitary measures already taken will be helpful. However, the certifying official will often need to also physically inspect the consignment in order to ensure compliance with phytosanitary regulations.

To continue, select Topic 4 from the Topics menu above or click here.